“Breathe life into tea”

Identify the qualities of each tea

Flavor and taste of picked tea leaves are affected by the weather, temperature and humidity.

We bring the best out of leave’s flavor by achieving careful production management.

Also, we are thorough on hygiene management by using latest machines, so that customers buy our products without any worries.

Information of finishing factory

【Finishing process of unprocessed tea】

Step1

When entering finishing process facilities

Change our clothes and pass through an air-shower room to prevent contamination.

Wash and disinfect our hands with alcohol.

We use automatic washing machine. Because of that, we don’t have to use our hands again and keep our hands clean.

Dry hands throughly with a paper towel.

Srep2

Total finish machine

We have introduced hygienic and latest model of finishing machine.

This process is to align the length and thickness of tea leaves though different nets.

Detach the dusts and fluff from green tea leaves. High class teas are shaped up by this process.

Major manufacturers does this process by assembly lines, but we try to finish it up carefully by different type of unprocessed teas.

Teas that are finished up sensibly can be good roasted.

Step3

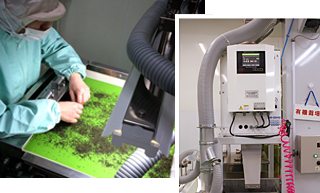

Color sorting machine

Notice the tea box.

Considering hygiene, we use stainless steeled box in order to avoid wood chips from getting in.

Selected tea leaves are brought out like this picture. The whitish stems are selected to the back and greenish stems are selected to the center part.

Kukicha (twig tea) that separated by this process is ranked and roasted. It is “Shiraore”.

Step4

Roasted

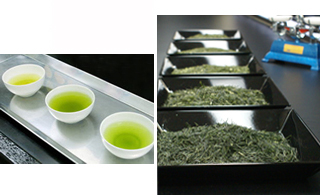

The taste of Igeta tea is obtained by tea masters who make a tireless effort.

This is the most important process for us.

We try to bring the flavors and tastes of each tea. And also taste the tea and fine-tune the machine over and over to find the perfect condition.

It requires experience, a sense of taste and smell.

However, flavors change depend on each dealers because they have own methods of firing and its machines.

Each dealer is going to give us different impression if using same tea leaves.

Step5

After we identify the features of each tea, blending ratio will be decided such as flavors, tastes and colors.

This work is all about tea master’s experience.

We thing imagining what you want to make is the most important thing or we cannot make it better.

Also, the ideal will be the symbol of the tea factory.

Step6

Blend

Next, the tea leaves are mixed when the blending ratio is settled.

And then, those are vacuum-packed and kept in cold storage.

Flavors will be better after cooled down than taste immediately after firing.

Step7

Finish

We taste the completed tea again in order to make sure customers like it. It is an intense moment.

Teas are discretionary items. Each tea makers have own features. Please find your favorite tea factories.

That’s so easy! Just buy and enjoy it, price is no object.

The tea might made by who have same good taste as you even if it is cheap.

If you find your favorite tea makers, there might no hit or miss. We hope the customers like the products while making teas.

Information of packaging factory

【products packaging process】

Step1

Food contamination check

We use high precision metal detector machine and check with our eyes thoroughly in order to give our customers safe and perfect products.

私たちが掲げる「安心・安全な商品づくり」の

最後の関所です。

Step2

Packed

(auto-packed machine)

With newest auto-packed machine, very hygienic packaging work is completed.

In addition, after the products are packed, we check packaging condition with our eyes.

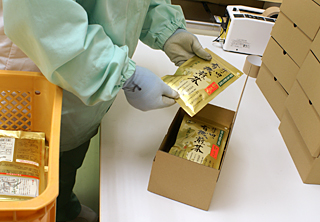

Step3

Boxing

(shipping preparation)

At last, we shift boxing process.

Each packaged products are boxed by types and prepared for shipping.

We check them one by one with our eyes again thoroughly. There are completed Igeta products with our pride and confidence.